Selecting the right material for sealing, insulation, vibration damping, or industrial gasketing can significantly impact…

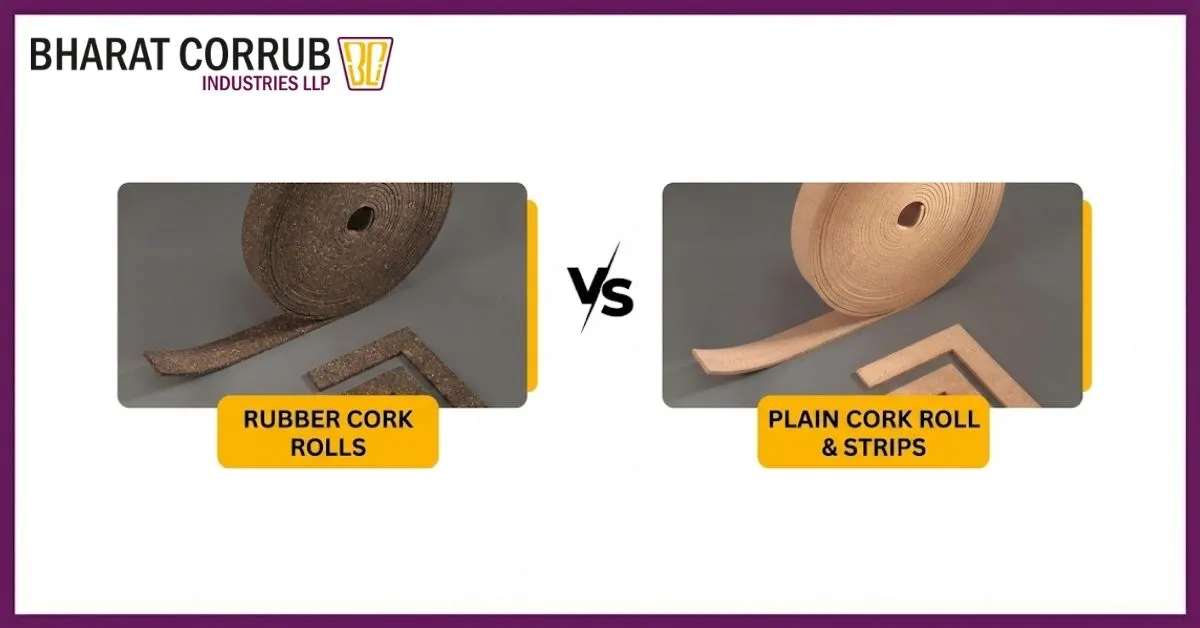

In industries where sealing, insulation, and durability are critical, the choice of material can make all the difference. Among the popular options, Rubber Cork Sheets and Plain Cork Sheets are widely used for gaskets, insulation, vibration control, and sealing solutions. While both share cork as a natural base, their properties, applications, and performance differ significantly. Let’s explore a detailed comparison to help you choose the right option for your industrial needs.

What is a Plain Cork Sheet?

A Plain Cork Sheet is made from natural cork granules bonded together, offering lightweight, flexible, and eco-friendly properties. It is known for:

- Excellent compressibility

- Thermal insulation

- Lightweight design

- Cost-effectiveness

Plain cork sheets are commonly used in flooring, pin boards, notice boards, and light-duty insulation where high strength is not required.

What is a Rubber Cork Sheet?

A Rubber Cork Sheet is manufactured by blending cork granules with synthetic or natural rubber. This fusion enhances the strength, elasticity, and durability of the sheet. Key features include:

- Superior oil and fuel resistance

- High tensile strength

- Vibration and noise absorption

- Longer service life

Rubber Cork Sheets are widely used in automotive, electrical transformers, and heavy machinery industries where strong sealing and flexibility are essential.

Rubber Cork Sheet vs Plain Cork Sheet

| Feature | Rubber Cork Sheet | Plain Cork Sheet |

| Material Composition | Cork + Rubber (synthetic/natural) | Natural cork granules only |

| Strength & Durability | High tensile strength, long-lasting | Moderate, less durable |

| Resistance | Oil, fuel, water, and heat resistant | Limited resistance to oil and water |

| Applications | Automotive gaskets, transformer pads, sealing | Flooring, notice boards, insulation |

| Flexibility | High elasticity due to rubber blend | Less flexible compared to rubber cork |

Applications of Plain Cork Sheet

Plain Cork Sheets are ideal for non-industrial and light-duty applications, such as:

- Flooring and underlayment

- Notice boards and pin boards

- Craft and decorative purposes

- Insulation in packaging and light machinery

Looking for durable and high-quality Rubber Cork Sheets? Contact us today for customized solutions that fit your industrial needs!

Applications of Rubber Cork Sheet

Rubber Cork Sheets are a preferred choice for industries demanding strength, resistance, and flexibility. Common uses include:

- Automotive engine gaskets

- Transformer core insulation pads

- Sealing materials in machinery

- Vibration and sound dampening in equipment

Which One Should You Chose?

- If your requirement is light-duty, cost-effective, and eco-friendly, then Plain Cork Sheet is sufficient.

- If your industry needs durable, oil-resistant, and vibration-absorbing solutions, then Rubber Cork Sheet is the best option.

At Bharat Corrub Industries LLP (BCI), we manufacture high-performance Rubber Cork Sheets that meet global industrial standards, ensuring long-lasting efficiency and reliability.

Frequently Asked Questions

Are Rubber Cork Sheets more expensive than Plain Cork Sheets?

Yes, Rubber Cork Sheets are generally costlier due to added rubber, durability, and higher performance.

Can Plain Cork Sheets be used for gaskets?

They are not recommended for heavy-duty gaskets but can be used in low-pressure, light-duty sealing.

Which industries benefit most from Rubber Cork Sheets?

Automotive, electrical transformer, and heavy machinery industries benefit the most.

Are both sheets eco-friendly?

Yes, both are eco-friendly as they are cork-based, but Rubber Cork Sheets include added rubber for strength.

Conclusion

Both Rubber Cork Sheets and Plain Cork Sheets serve important roles in industries and daily applications. While Plain Cork Sheets are cost-effective for lightweight uses, Rubber Cork Sheets provide superior performance in demanding industrial conditions.